Optimized Forming Tool Design

Boosting Muffler Production for the Two-Wheeler Industry

Project Overview

India’s growing demand for two-wheelers requires manufacturers to strategically plan for increased production capacity to remain competitive. While working as a Student Engineer at Badve Engineering, I contributed to the development of a new forming tool to help our customer expand muffler production and meet market demands.

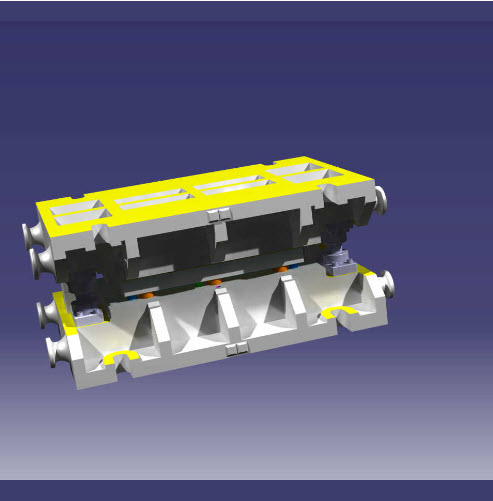

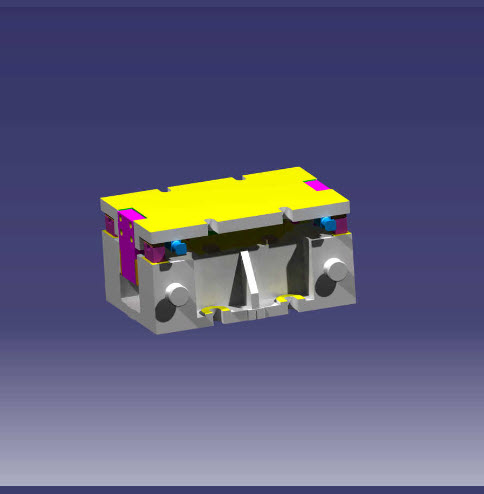

The existing production process involved four forming stages, designated as OP-10 through OP-40. Based on the customer’s requirements, I designed and optimized new forming tools, ensuring enhanced efficiency and scalability.

Key Achievements

The results of my design included:

- 37% increase in production capacity, enabling faster throughput.

- Future-proof tool design, ensuring long-term adaptability and robustness.

- Successful validation through both physical and computational testing, confirming performance reliability.

This project provided valuable experience in tool design, process optimization, and manufacturing scalability, ultimately contributing to improved production efficiency and cost savings for the company.

Forming Process Stages

Forming Step 1

Forming Step 2

Forming Step 3

Forming Step 4